Description

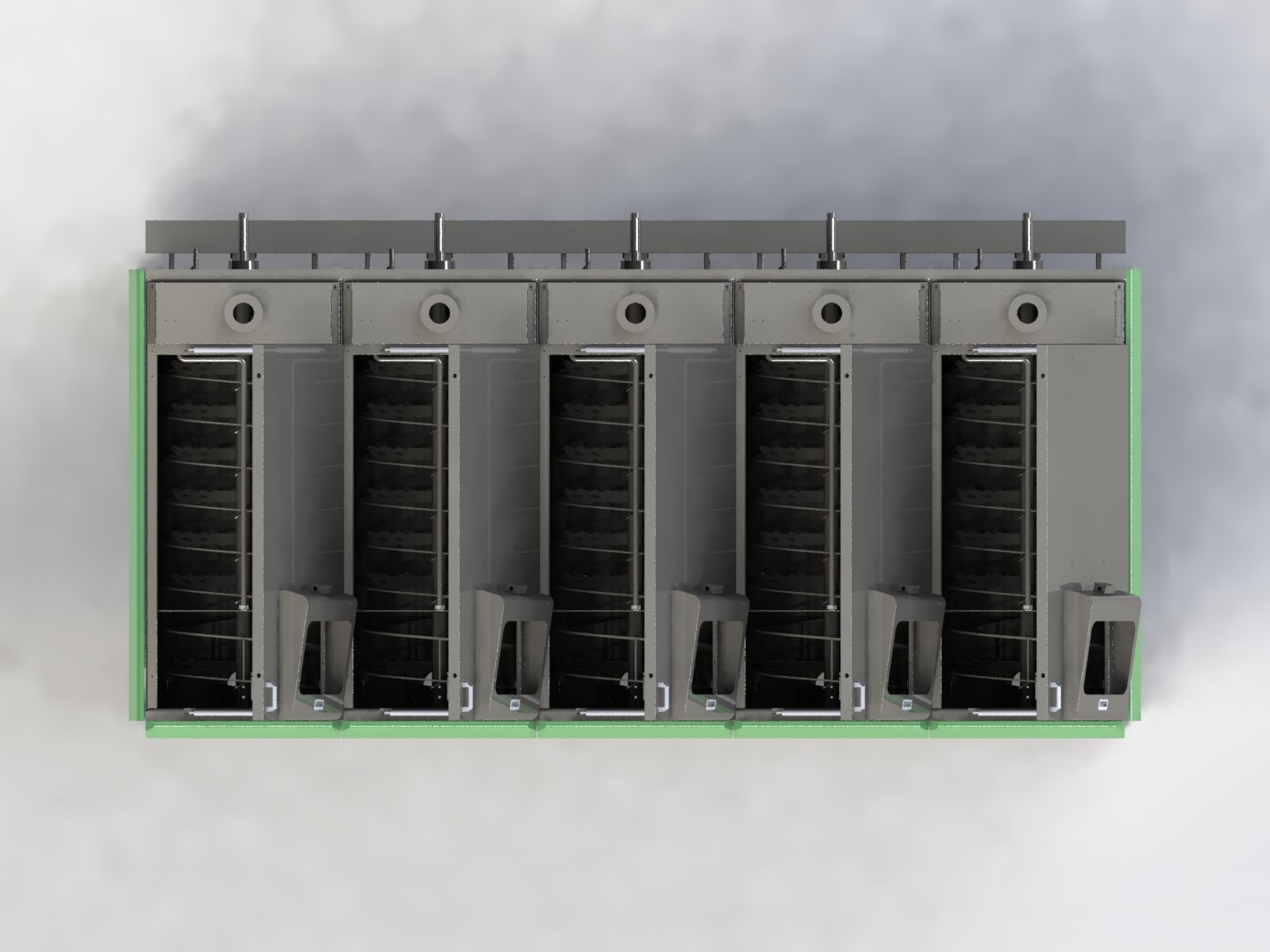

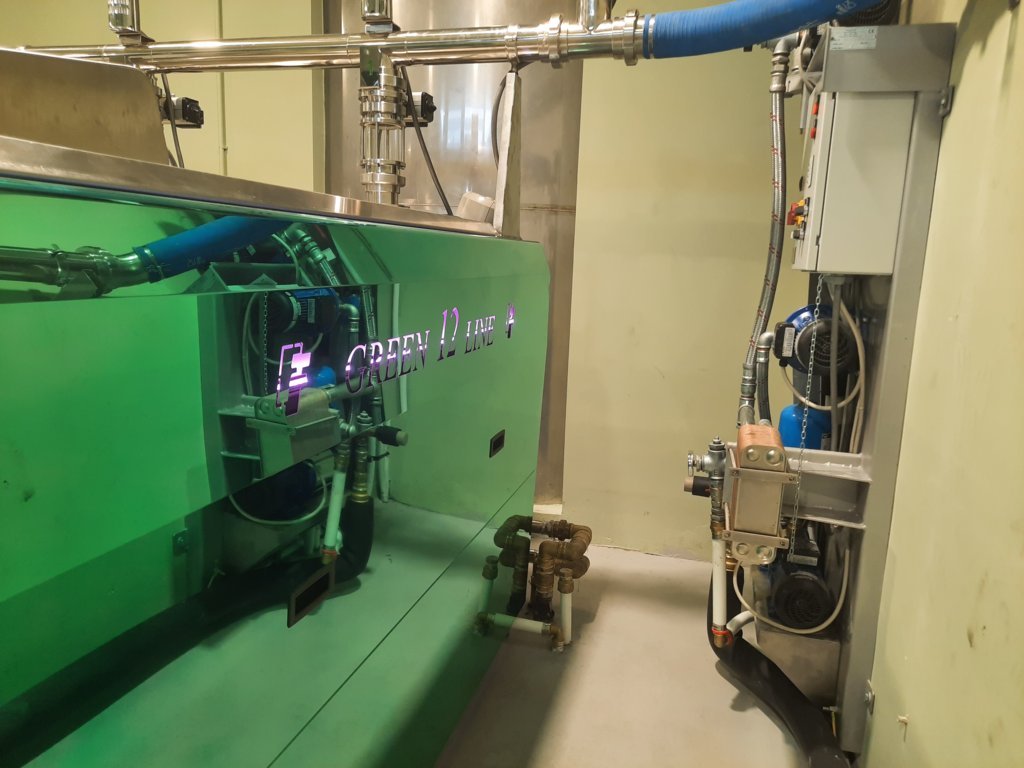

The 1200 Kg / 1300 lt F.lli Ferri malaxers have been designed and engineered to guarantee the best performance in terms of quality of extracted oil and in terms of quantity. They are suitable for both batch and continuous processing. Object of study was the design of the main reel of the malaxer designed with an innovative design of the blade that helps during the mechanical action of the reel rotation, the cutting of the fat molecule and the formation of oil droplets. The number of reel revolutions also varies according to the diameter of the malaxer, calculated on the basis of the peripheral speed of the reel. Another object of study was the thermal conditioning system designed to ensure that there are no shaded areas in the malaxer, thus significantly reducing the malaxing times. The malaxer is totally closed in order to reduce the contact points of the pulp with oxygen and subsequently obtain an oil with low peroxides. Even the tube loading system allows to eliminate the points of contact with oxygen and the pump loading system guarantees a soft loading of the dough. The cover is equipped with a gas spring system for 180 ° opening; the washing of each malaxer is guaranteed by rotating heads which, connected to a high pressure pump, will allow a homogeneous washing of the whole tank; the bottom unloading with full bore represents another advantage for these malaxers as they speed up the final part of the unloading.

Here are the technical characteristics of the malaxer:

- Steel tank and body with 1200Kg / 1300Lt capacity

- Stainless steel lid connected to stainless steel hinges and gas springs that allow opening along the entire length at 180 °

- Reel with innovative design entirely in stainless steel and blade for pushing down towards the discharge

- Inspectionable porthole with illuminated glass and defrosting system

- Washing system with 3 stainless steel rotating heads connected to a high pressure pump

- Probe for temperature detection

- Maximum level probe

- Minimum level probe

- Pneumatic drain valve with signaling box of 150 with food seal

- Pneumatic filling valve in stainless steel dn80 or dn100 with signaling box and food seal

- Sight glass for the passage of the pasta

- System with luminous turret to indicate the working status (full malaxer, unloading and loading)

- Lowara inverter cicrcolatore for thermal conditioning operating with permanent magnets for energy saving

- Stainless steel pipes for thermal conditioning

- Made in Italy gearmotor with high energy efficiency IE3 motor

- Wiring on the machine with anti-oil and anti-cut PVC sheaths

- Stainless steel panels with 4mm pitch IP69 display for visual process communication (optional)

- Front and side panels in green galvanized stainless steel

- The name green is not accidental and recalls both the color of the olive but is connected to the concept of energy saving for which these kneaders have been conceived and designed. In fact, the use of Ie3 motors, inverter circulators allows considerable energy savings; while the thermal conditioning system and their modular assembly allows a considerable saving of Kcal.

- Installed power 2.2 Kw

Reviews

There are no reviews yet.